Onan generators are designed and manufactured by Cummins, and they have become the most preferred choice for motorhomes and RVs to create a power backup system. This generator is enough to operate electronic appliances and charge phones and laptops.

It can be easily turned on with the help of a start button. However, if the generator dies as soon as you release the start button, there are a few solutions that can help you out!

Onan Generator Dies When Start Button Is Released

1. Voltage

If the generator turns off as soon as the start button is released, it means that there is no output from the generator. You can easily confirm the voltage with the help of a voltmeter by connecting it to the generator’s output.

Once the voltmeter is connected, take the reading to determine if the current is passing through. In case there is no reading, you have to check for the disconnected wires – the disconnected wires have to be connected again.

2. Starter Switch Is Damaged

If the wires are connected properly but the generator is still not working consistently, there are chances that the starter switch is damaged and isn’t working. The starter switch is responsible for operating the starter system and also controls the power source.

However, when the starter switch is damaged, it won’t be able to control the power source, resulting in the generator’s operational issues. The solution is to get the starter switch repaired, but replacement is a more reliable solution.

3. Overload

In case the generator starts but turns off, it could be caused by overloading. Every generator has been designed with a specific output capacity. So, when the load is more than the generator’s wattage power, the engine will stop running after a few seconds.

In particular, it happens when the circuit breaker is not working properly because it’s responsible for cutting off power whenever there is an additional load.

The immediate solution is to reduce the number of devices connected to the generator. Then, check the circuit breaker and make sure it’s working properly – it will ensure that the power is cut off as soon as the generator gets an overload.

If the circuit breaker is damaged, it has to be replaced.

3. Oil

The fuel and oil are essential for the generator to work. So, if there is an oil shortage in the generator, it won’t start or will stop working after a few seconds. In addition to startup issues, the shortage of oil can result in poor lubrication.

As a result, it can cause premature wear and tear to the engine. The Onan generators are actually designed with the low-oil shutdown feature, which automatically turns off the generator or prevents it from working consistently.

So, when the generator turns off after a few seconds, you’ve to check the engine oil level in the generator. If the oil levels are lower than the required value, you have to top up the oil.

On the other hand, if you recently topped up the oil, there are chances that the oil is dirty and needs to be changed.

4. Coolant Level In Radiator

The 30% of fuel added to the generators is used for energy production and the rest of the fuel is removed by heat and gas. For this reason, you have to be considerate about the cooling system, such as a radiator.

That’s because the radiator is responsible for cooling down the motor and engine, and prevents overheating. In particular, it happens when there is a low coolant level.

For this reason, we recommend that you locate the radiator and check the coolant level. If the coolant level is low, you have to add more coolant to the radiator to prevent overheating.

This is important because overheating can lead to intermittent operations of the generator.

5. Fuel Level

The fuel is important to operate the generator, and if it dies as soon as you release the start button, there are chances that the fuel level is too low. So, we recommend that you check the fuel level and add more if the fuel level is too low.

On the other hand, if the fuel level is sufficient, you have to check the fuel line because it might be clogged. For this reason, we recommend that you locate the fuel line and clear the clogging to streamline the flow of fuel.

6. Fuel Tank

A damaged or dirty fuel tank can also be the reason behind a constantly-dying engine. That’s because the dirty fuel tank can cause clogging of the generator and/or fuel lines. Usually, the fuel tank gets dirty when you use low-quality fuel to power the generator.

So, the solution is to empty the fuel tank, clean the fuel system, and add new but high-quality fuel to optimize the generator’s operations.

7. Carburetor

The carburetor is installed on the back of the generator and is responsible for providing the optimal mixture of fuel and air that operates the generator.

However, if the carburetor is damaged or clogged, it won’t be able to provide the fuel and air mixture to the generator, and the generator will turn off as soon as the start button is released. The solution is to get the carburetor replaced with a new one.

On the other hand, if there is no physical damage to the carburetor, it’s likely that it’s clogged. The carburetor gets clogged by using dirty fuel lines or degraded fuel. Having said that, the dirty or clogged carburetor can be cleaned with the help of a fuel system cleaner.

8. Battery

The generator is integrated with a battery, and if the generator stops working after you release the start button, it’s likely that the battery connections are damaged.

The first solution is to check the battery connections and make sure that all the connections are done properly. If some wires have come off, you have to reconnect them.

In addition to this, you must clean the battery terminals with the help of a contact cleaner to make sure the current or voltages pass through.

9. Choke

The choke is a lever that provides fuel to the engine when it’s cold as it creates a rich air-to-fuel ratio. However, when you release the start button, the choke has to be deactivated.

On the other hand, if the choke remains activated after you start the generator, it won’t be able to power the generator or produce a constant current.

So, if the generator doesn’t stay on, you should check the choke and turn it off manually to make sure it keeps running.

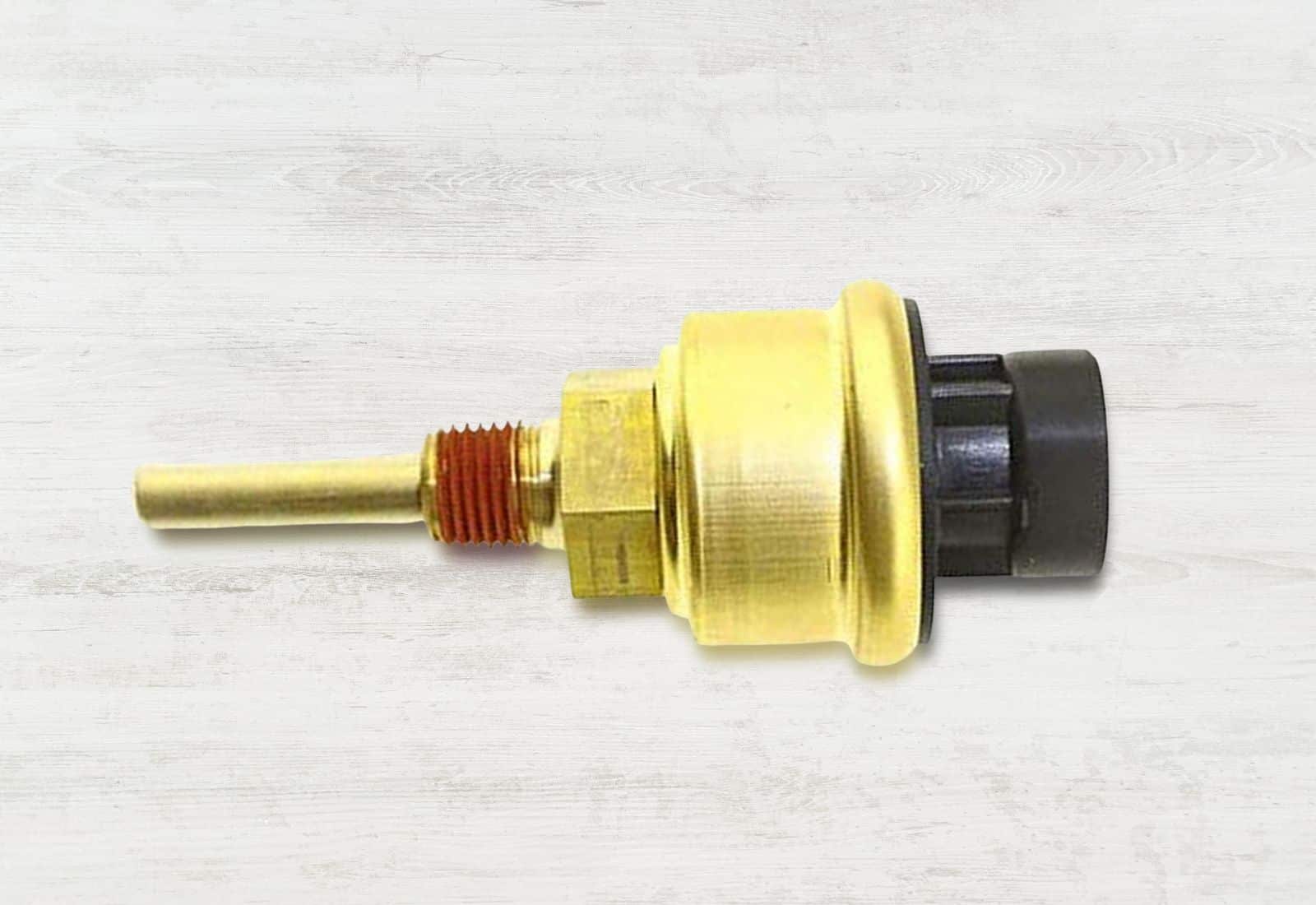

10. Oil Pressure Switch

A damaged oil pressure switch will cause inaccurate generator operations and can lead to failure to operate the engine. As a result, the generator will lose power as soon as the start button is released.

The solution is to replace the damaged pressure switch. Also, to prevent this damage, you must select oil with the correct viscosity rating.

11. Coolant Sensor

The damaged or malfunctioning coolant sensor can also lead to operational issues in the generator. In most cases, this issue is caused by overheating of the coolant while the radiator’s interior is still cool.

For this reason, you have to check if the switch is closing and opening correctly or not. If the switch isn’t opening or closing, it means that the sensor is damaged and should be replaced.

In addition to this, you’ve to look for broken wires in a circuit. If there are broken or disconnected wires, you should reconnect them to make sure the sensor works.

The Bottom Line

Onan generator is a reliable choice and the startup issues can be easily resolved as long as you check all the related components. To prevent this issue, you must ensure the sufficient fuel level in the generator and make sure the choke lever is deactivated once the generator starts.

On the other hand, if you aren’t able to resolve the startup issue, it’s better that you hire a professional or call Onan customer support for free support.