The Brake Buddy is an excellent supplemental braking system that significantly reduces the motorhome and the towed vehicle’s stopping distance. It is made of quality materials and is quite durable.

If you intend to purchase the Brake Buddy system, it is important to familiarize yourself with the problems that you are likely to face. This troubleshooting guide offers a look at some of the most common issues associated with this braking system.

Luckily, some problems are relatively milder and can be fixed at home. Read on to learn more about them!

Brake Buddy Troubleshooting

Some common Brake Buddy system problems are mentioned in the section below.

1. Electrical Issues

It turns out that electrical issues are quite common with the Brake Buddy supplemental braking system. In fact, it is the leading reason for most problems in the system. In most cases, the system stopped working due to electrical issues.

Of course, anything with wires has the potential to go bad as the wires are susceptible to damage and may also go loose. Therefore, start troubleshooting the system by checking its wiring first.

To check the wiring, you will need to open the Brake Buddy supplemental braking system. A screwdriver will come in handy for this purpose. Remove all the screws and keep them in a container, so you won’t have to search for them later.

Once you have opened the Brake Buddy supplemental braking system, check if they show any signs of damage. Are the ends exposed? Do the wires feel hot? Is anything unusual?

If the wires appear damaged, you must repair or replace them to bring the supplemental braking system back to life.

- Repairing Wires

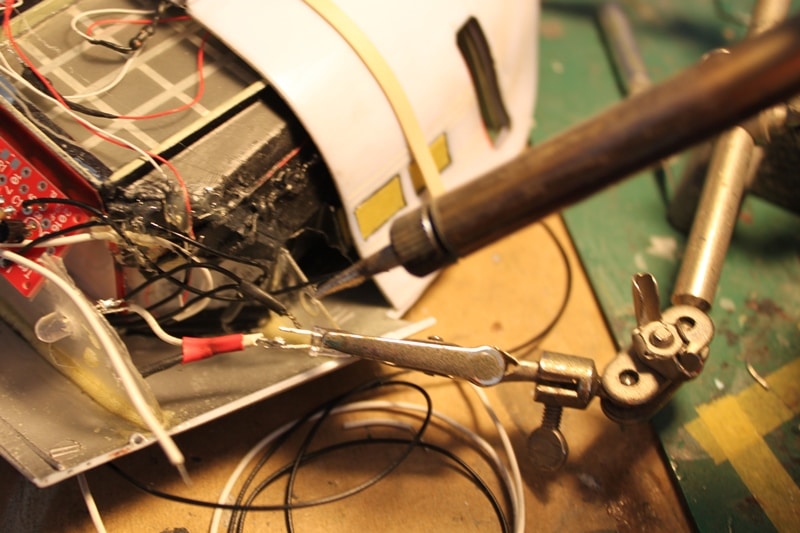

The good news for you is that you don’t need to replace the entire wire in case of minor damage. You can also repair it using a soldering gun.

Some people recommend using glue to repair a wire. This may work well sometimes, but it causes additional problems most of the time.

This is because the glue is an insulator and can break the electric connection between the wires. When the connection breaks, no current will flow through the wires, and as a result, the Brake Buddy supplemental braking system will stop working.

A soldering tool, on the other hand, is a preferred option as it puts the filler metal and connects the wires. The soldering process is quite simple. All you need to do is join the wires and heat them to join them permanently. When done properly, it can turn two separate wires into one.

- Safety Measures

It is important to take safety measures before starting the soldering process. Make sure to wear safety glasses to keep your eyes safe in case the solder material splashes.

These tools produce fumes and dust that are harmful to your eyes and can cause health problems. If you experience irritation in the eyes or difficulty in breathing, seek medical help at the earliest.

It goes without saying that the tip of the soldering tool is very hot. It reaches ultra-high temperatures of up to 400 c and can give you a nasty burn if not handled properly. Never use it on flammable material.

Just attach the soldering tool to the broken wire for a few seconds. This will establish a firm connection between the wires.

- Repairing Wires Without Soldering Tool

If you do not have a soldering tool at home or are skeptical about it, you’d be glad to know that you can repair wires even without using it. The first step is to remove the insulation of the wires. You can do this with the help of insulation stripping pliers.

Some people make a common mistake of using a knife or some other sharp object for this purpose and end up damaging the wires.

Once done, use a wire connector to establish a connection between the wires of your Brake Buddy supplemental braking system.

As its name implies, a wire connector connects the wires and creates a connection between them. Just twist the wires and insert them into the connectors to connect them.

2. Faulty Fuse

Apart from the wiring, you will want to take a look at the fuse as well. Like most equipment nowadays, the Brake Buddy supplemental braking system also comes with a fuse for protection in case of power surges.

The fuse breaks the circuit and blows out to protect the braking system. Since it is designed in such a way that it blows itself out, the chances are that a blown-out fuse is the culprit.

To check the fuse, you will have to remove it from the Brake Buddy supplemental braking system. It would be a good idea to refer to the user manual before removing it.

Once you have removed it, take a closer look at it. If the wire of the fuse appears melted or you see a clear gap, it has gone bad and must be replaced.

If you have a voltmeter, you can use it to test the fuse of your Brake Buddy supplemental braking system. A voltmeter has leads that are to be connected to the fuse.

You will see a reading on the voltmeter’s display as soon as you connect the leads. Compare the reading to the recommended reading mentioned in the user manual. If the reading keeps fluctuating, the fuse is defective.

A blown-out fuse cannot be fixed. So, you will have to install a new one to resolve the problem. The replacement process is quite simple and won’t take much of your time either.

3. Check Connections

If there is something wrong with the connection, the Brake Buddy supplemental braking system won’t work properly. It is important to install and connect it to both vehicles the right way.

The steps regarding its installation are mentioned in its user manual. So, go through the manual before installing it. If you are unsure about it, you can visit a workshop, and they will do it for you.

4. Adjust Sensitivity

Choosing the right sensitivity is as important as the proper installation of your Brake Buddy supplemental braking system. If the towed vehicle moves too fastly or slowly, consider changing the sensitivity settings until you find the perfect one.

The Bottom Line

Users have reported many issues while using the Brake Buddy supplemental braking system. Wiring issues, blown-up fuses, and sensitivity problems are some of them that you may encounter.

If the wires are damaged, fix them with a soldering tool or get them replaced. We have covered all these problems and their solutions in this article.

My unit doesn’t seem to be activating when I brake hard

I also noticed the first two lights don’t light when setting it up

Mine will not air up or bleed the brakes. Has a burned hole on top of the unit about the size of a dime.

brakes lock up going down hwy and we are not hooked to the motorhome. just had it installed and all looks correct

do i need a brake controller in my rv to use my old style brake buddy or what activates my brake buddy or tells it to work